In the fast-paced realm of commercial laundry operations, efficiency, quality, and consistency are non-negotiable. For businesses in the hospitality industry, institutional sectors, and commercial laundry services, industrial steam iron presses have emerged as indispensable tools that redefine garment finishing standards. As a global leader in smart laundry ecosystems, Flying Fish has engineered industrial steam iron presses that embody the seamless integration of advanced technology, user-centric design, and sustainable performance. These machines are not mere upgrades from traditional ironing methods but transformative solutions that enhance operational efficiency while delivering flawless results for a wide range of fabrics. This article delves into the core features of industrial steam iron presses, exploring how each element contributes to their superior performance and why they have become the preferred choice for businesses seeking to optimize their laundry processes.

Versatile Ironing Capability for All Garment Areas

One of the most prominent core features of industrial steam iron presses is their ability to efficiently iron all parts of garments. Unlike conventional ironing tools that often struggle with hard-to-reach areas or require multiple adjustments to cover the entire garment, industrial steam iron presses are specifically designed to adapt to various garment structures. Whether it’s the collars, cuffs, and shoulders of shirts, the plackets and pocket edges of jackets, or the creases and waistbands of trousers, these machines achieve full, gap-free ironing through precise pressure distribution and adaptive design. This comprehensive ironing coverage ensures that every detail of the garment meets rigorous standards of smoothness and crispness, satisfying the strict aesthetic requirements for clothing in commercial laundry services—particularly in sectors like hospitality, where the appearance of linens and staff uniforms is of paramount importance.

Superior Efficiency and Ironing Results Compared to Traditional Methods

Industrial steam iron presses represent a qualitative leap in efficiency and ironing performance when compared to the traditional "ironing table + iron" combination. Traditional ironing relies heavily on manual operation, which is labor-intensive and results that are highly dependent on the operator’s skill level, often leading to uneven ironing and residual wrinkles. In contrast, industrial steam iron presses minimize manual intervention through automated pressing mechanisms, significantly boosting operational efficiency. Within the same timeframe, these machines can process far more garments than traditional methods, effectively meeting the large-scale garment finishing demands of commercial laundry settings and helping businesses substantially increase productivity. Meanwhile, through stable pressure control, uniform steam distribution, and scientific pressing angle design, the equipment ensures consistent, smooth ironing results for every garment—removing wrinkles more thoroughly and achieving a higher level of crispness that surpasses what traditional ironing can deliver. This dual advantage of high efficiency and superior quality allows businesses to reduce operational costs while providing better services to customers, enhancing their market competitiveness.

Powerful Dehumidification System for Dry, Shaped Garments

Another core component of industrial steam iron presses is a powerful dehumidification system, which is crucial for achieving rapid garment shaping and dry results. During the ironing process, steam moistens the fabric fibers; if moisture is not promptly removed, it not only compromises the final shape of the garment but also risks dampness and mold growth—especially in high-humidity environments or large-scale continuous operation scenarios. The powerful dehumidification system integrated into Flying Fish’s industrial steam iron presses quickly extracts and expels moisture from garments during the pressing process, ensuring they reach a dry state immediately after ironing. This system not only improves the quality of finished garments, keeping them crisp, wrinkle-free, and free of dampness but also shortens subsequent drying times, further enhancing the overall efficiency of the laundry workflow. Additionally, a dry ironing environment helps protect fabric fibers, reducing damage caused by moisture and extending the lifespan of garments.

High-Quality Pneumatic Components and Scientific Steam Pipeline Design

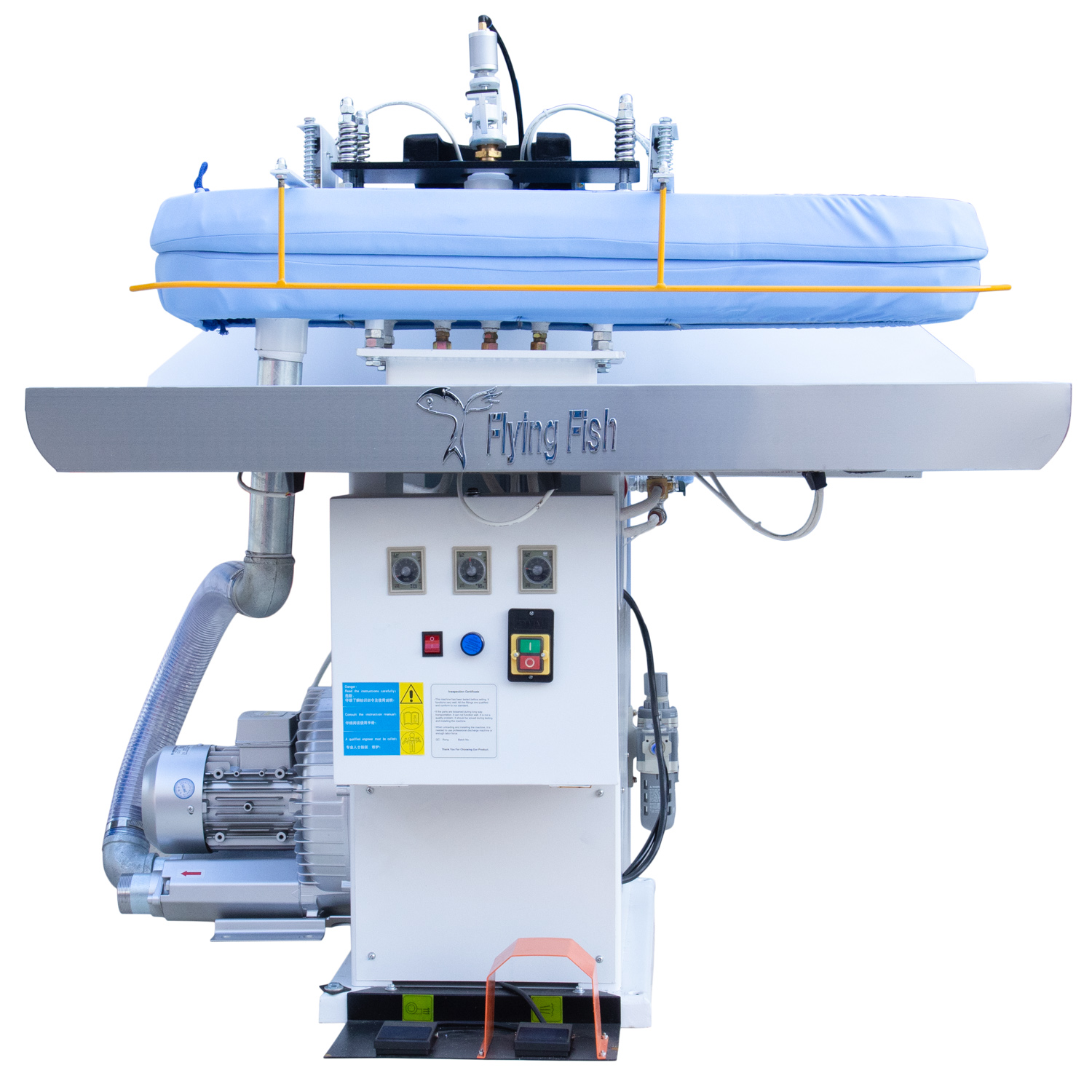

The stable operation of industrial steam iron presses relies on high-quality core components and rational structural design, with high-quality pneumatic components and a scientific steam pipeline structure being key features. In manufacturing its equipment, Flying Fish selects premium pneumatic components from the industry—known for their durability and low failure rates. These components ensure the machines operate reliably even under the long-term, high-intensity demands of commercial environments, minimizing downtime due to component damage and reducing maintenance costs for businesses. Simultaneously, the equipment adopts a optimized steam pipeline layout, which ensures stable pressure and uniform distribution during steam transmission, avoiding issues such as insufficient local steam or excessive pressure and thus guaranteeing consistent ironing results. Furthermore, the machines require an air compressor for control and operation; the synergy between the air compressor and pneumatic components enables precise control of pressing movements, allowing operators to easily complete ironing tasks for various garments and improving operational convenience.

Rapid Heating and Low Energy Consumption for Energy Efficiency

In today’s business landscape, where sustainable operations are a priority, energy efficiency has become a key consideration for businesses selecting laundry equipment. Industrial steam iron presses stand out as an ideal choice, combining high efficiency with energy-saving benefits through their core features of rapid heating and low energy consumption. These machines utilize advanced heating technology to quickly reach the set ironing temperature in a short time, eliminating the need for prolonged preheating and effectively reducing startup time—enhancing overall operational efficiency, especially in commercial laundry settings that require frequent equipment on/off cycles. Leveraging years of experience in sustainable technology R&D, Flying Fish has achieved significant energy savings by optimizing the equipment’s thermal circulation system and incorporating energy-efficient components. Compared to traditional ironing equipment, industrial steam iron presses reduce energy consumption while maintaining high productivity, helping businesses lower operational costs and uphold environmentally friendly practices in line with international standards such as EU Ecodesign directives.

Computer-Controlled Steam Pressure Adjustment

To meet the ironing needs of different fabrics, industrial steam iron presses are equipped with computer-programmed steam pressure adjustment—a smart design that ranks among their core features. Different fabric types, such as cotton, linen, silk, and chemical fibers, require varying steam pressures; improper pressure can cause fabric damage or subpar ironing results. Industrial steam iron presses feature built-in computer systems that allow operators to freely adjust steam pressure based on fabric material, thickness, and other characteristics. Whether it’s heavy cotton garments requiring high-pressure steam to remove stubborn wrinkles or delicate silk fabrics needing gentle, low-pressure ironing, precise pressure adjustment ensures optimal ironing parameters. This intelligent function lowers the skill threshold for operators, enabling high-quality ironing without extensive experience, while also protecting fabric fibers to maintain the original texture of garments while achieving a crisp, smooth finish.

Customizable Pressing and Dehumidification Time Settings

Addressing the varying characteristics of different fabrics, industrial steam iron presses offer customizable pressing and dehumidification time settings—a flexible feature that enhances their adaptability to diverse ironing needs. Fabrics differ in fiber structure, thickness, and water absorption, requiring tailored pressing and dehumidification durations. For example, thick cotton garments need longer pressing times to eliminate wrinkles completely and extended dehumidification periods to expel moisture, while lightweight chemical fiber garments achieve ideal results with shorter cycles. Industrial steam iron presses allow operators to freely set pressing and dehumidification times via the control panel, enabling personalized parameter configuration for specific fabric types. This flexibility ensures optimal ironing results for every garment while preventing fabric damage from improper settings, further enhancing the equipment’s practicality and versatility.

Industrial steam iron presses have become indispensable tools in commercial laundry operations, thanks to their comprehensive core features. From versatile ironing coverage for all garment areas and superior efficiency compared to traditional methods, to a powerful dehumidification system that ensures dry, shaped garments; from high-quality pneumatic components and scientific steam pipeline design that guarantees stable operation, to rapid heating and low energy consumption for sustainability; and from computer-controlled steam pressure adjustment to customizable pressing and dehumidification times—each feature is engineered to boost operational efficiency, improve ironing quality, enhance adaptability, and reduce costs. As a global leader in smart laundry ecosystems, Flying Fish integrates precision engineering with environmental responsibility, developing industrial steam iron presses that meet international quality and environmental standards while providing practical solutions for businesses in hospitality, commercial laundry services, and beyond. Choosing a high-quality industrial steam iron press means embracing an efficient, high-performance, and sustainable operational model—one that helps businesses stand out in a competitive market and achieve long-term, stable growth.

Table of Contents

- Versatile Ironing Capability for All Garment Areas

- Superior Efficiency and Ironing Results Compared to Traditional Methods

- Powerful Dehumidification System for Dry, Shaped Garments

- High-Quality Pneumatic Components and Scientific Steam Pipeline Design

- Rapid Heating and Low Energy Consumption for Energy Efficiency

- Computer-Controlled Steam Pressure Adjustment

- Customizable Pressing and Dehumidification Time Settings